|

|

|

|

|

|

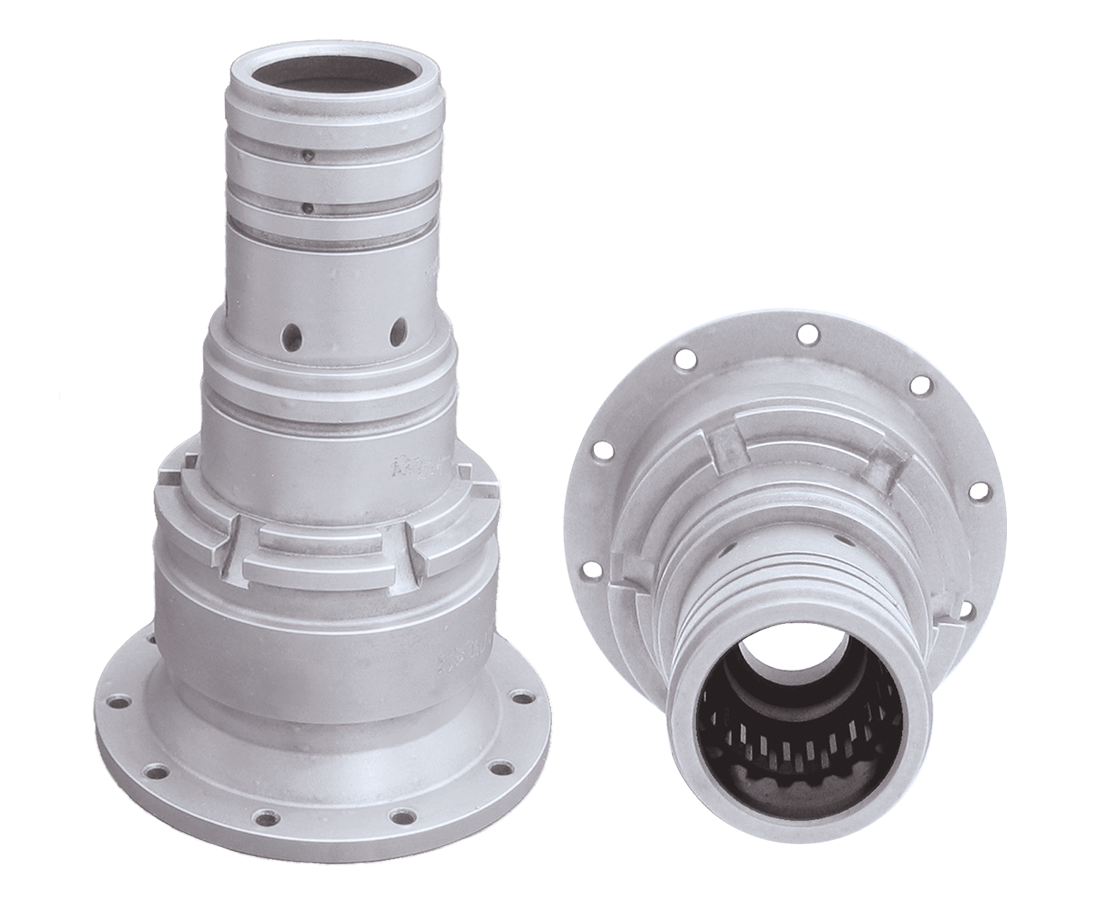

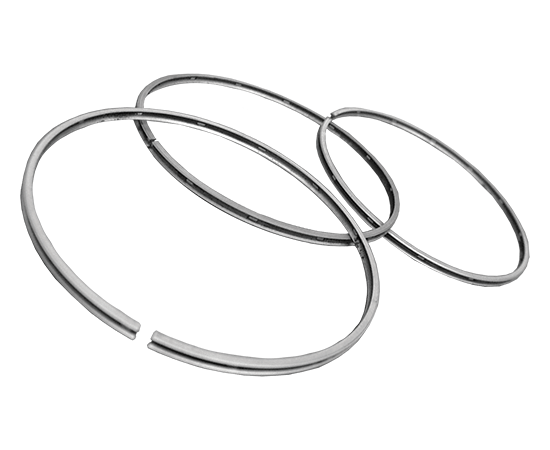

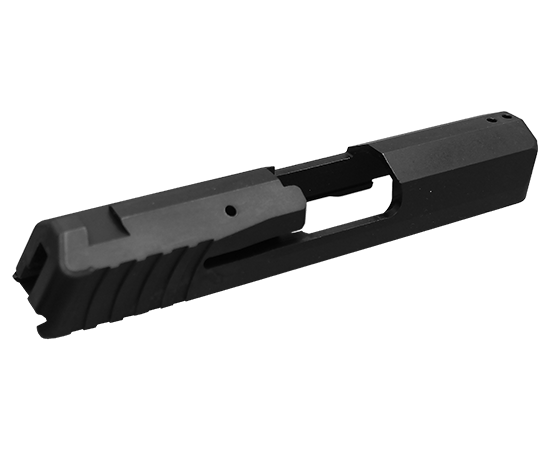

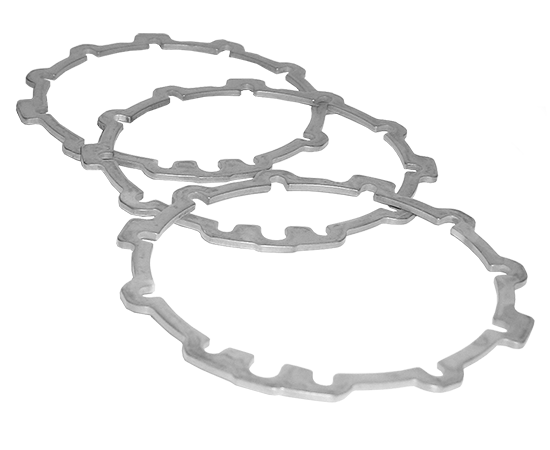

| Nozzle Flash Suppressors | Oil Rings | Pipe for Drilling Equipment | Pistol Slide | Turbo Rings, Unison Rings | |

|

|

|

|

|

|

| NITRIDING-NITROCARBURIZING | VACUUM | COATING | INDUSTRIES WE SERVE | SOLUTIONS PROVIDER | RFQ |

- FURNACES & TECHNOLOGIESFIND OUT MORE ABOUT OUR FURNACE AND TECHNOLOGIE SOLUTIONS

- HEAT TREATING SERVICESFIND OUT MORE ABOUT OUR HEAT TREATING SERVICES

- PROCESS & FLOW CONTROLSFIND OUT MORE ABOUT OUR PROCESS AND FLOW CONTROL SOLUTIONS

- SERVICE & SUPPORTLOOKING FOR SERVICE OR SUPPORT ON OUR PRODUCT AND SERVICES ?

- INDUSTRIES & PROCESSES

- COMPANYFIND OUT MORE ABOUT NITREX AND WHO WE ARE