Nitriding is a process of diffusing nitrogen atoms into the metal surface. Nitrogen is plentiful on Earth, however, in nature it exists as a two-atom molecule, chemically inert and too large to penetrate the surface. Hence nitriding technologies focus on the source of nascent (atomic) nitrogen.

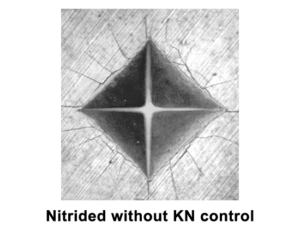

The main objective of nitriding is to increase the hardness of the component’s surface by enriching it with nitrogen. Regardless of the method, nitriding is a process of diffusing nitrogen into the metal and such diffusion, once individual atoms of nitrogen have penetrated the surface, continues as long as the temperature is high enough, and there is a fresh supply of nascent nitrogen on the surface. In other words, the diffusion is basically the same in all nitriding, while the difference lies in the supply of nitrogen. The latter has a fundamental influence on the resultant properties of the surface.