THE G-M ADVANTAGE

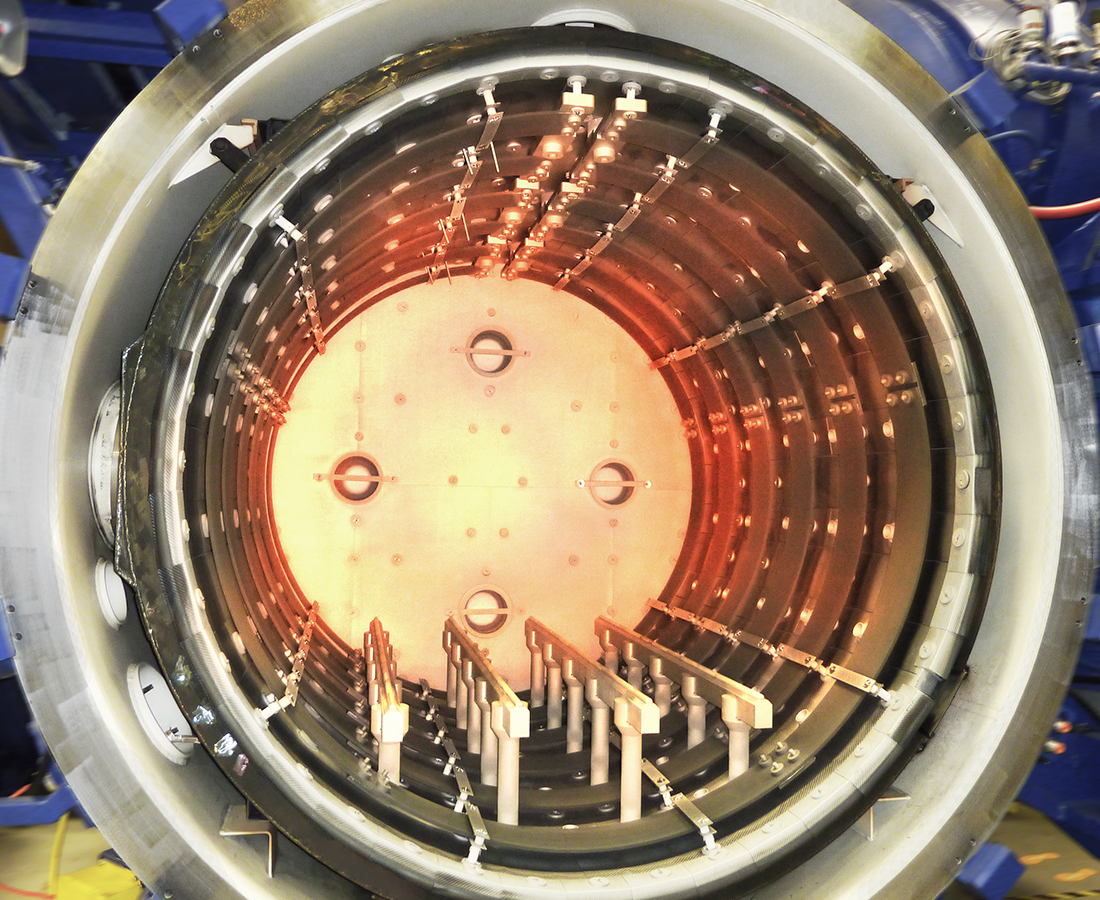

- One-piece, heavy-duty, double-wall plenum design provides a high-efficient, more uniform cooling gas flow

- Single-wall (plenum-less) and double-wall hot zones built with 30% thicker sheet metal assures structural integrity and eliminates distortion from heating and cooling cycles on the plenum, while reducing movement and damage of the hot face, insulation or shield pack

- Patented screw-in venturi graphite and moly nozzles surround the hot zone for higher velocity with better and more uniform gas distribution

- Screw-in nozzles also reduce the likelihood of breakage and falling out, eliminating the need for retaining wire pin holders

- Patented “two-point” heating element support system allows the element to “float” reducing stress, potential grounding, and arcing caused by element warping, tilting, and hanger rotation

- Insulation, graphite element supports, and nozzles can be easily replaced or repaired by hand without tools for easy maintenance and longer component life

- Use of advanced materials and designs reduce the need for frequent maintenance

- High-efficiency insulation and an all-metal shielding with channel separators minimize heat loss and reduce energy costs

- 3D scanning measurement technology replicates the existing hot zone with accuracy, ensuring that critical hot zone tolerances are maintained

- CFC leading edge is standard and available optionally to cover the rest of the insulation