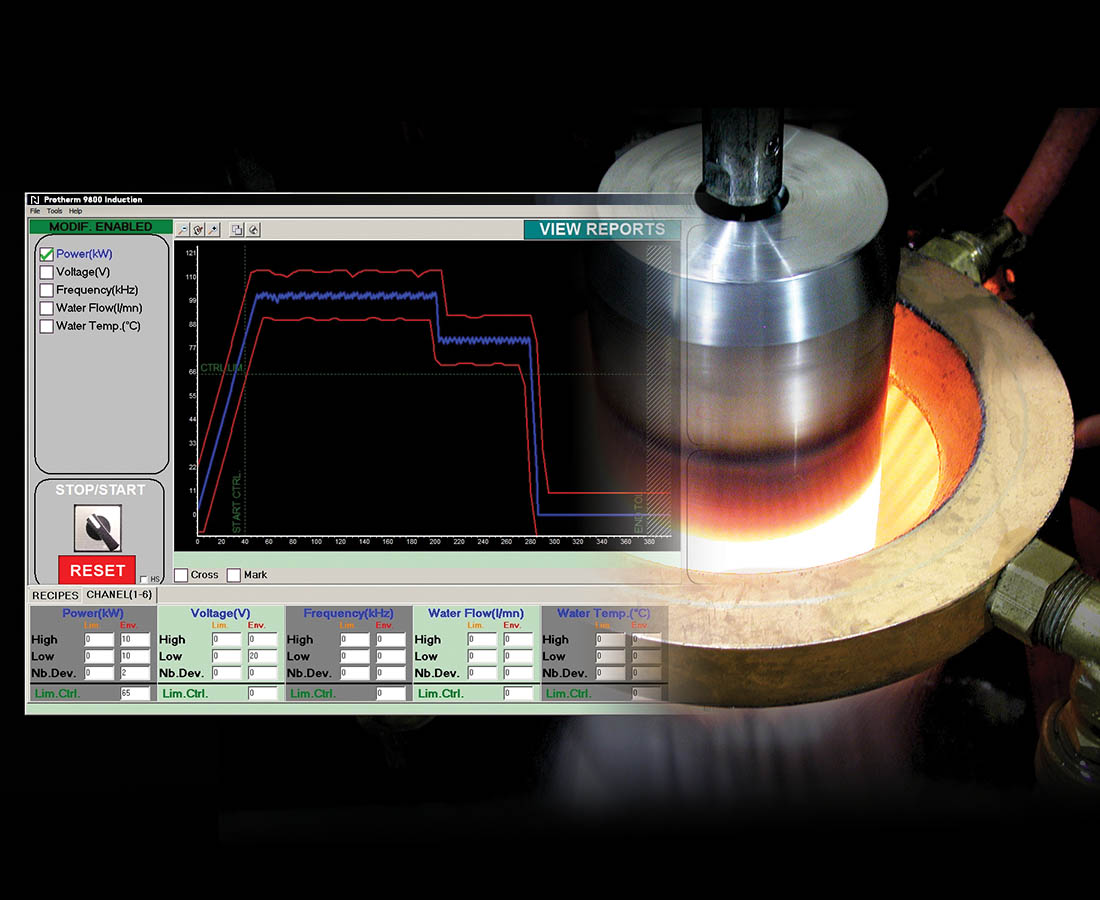

- ACCURATE, CONTINUOUS, AUTOMATIC MEASUREMENT

PROTHERM 9800 INDUCTION monitors current, voltage, and frequency to the coil in real-time, enabling to determine whether uniform heating, proper flux density, and depth are achieved or not

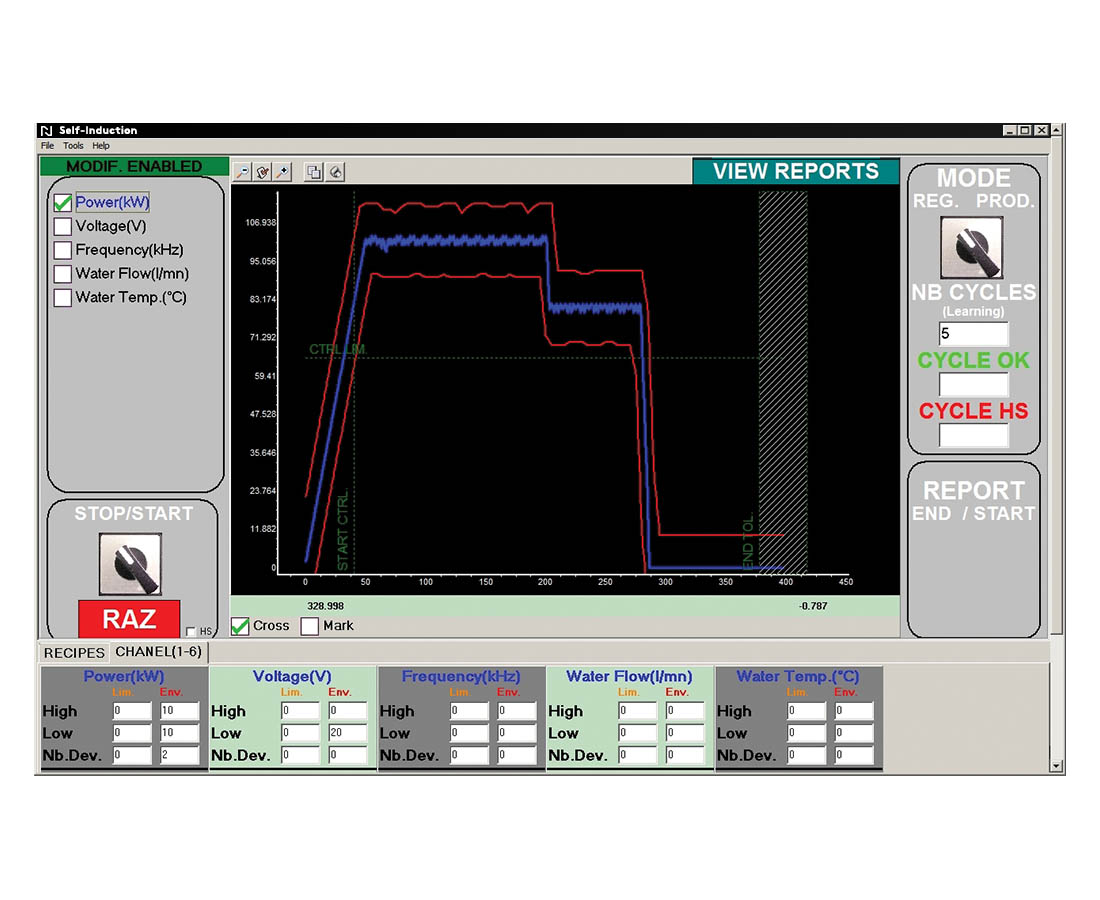

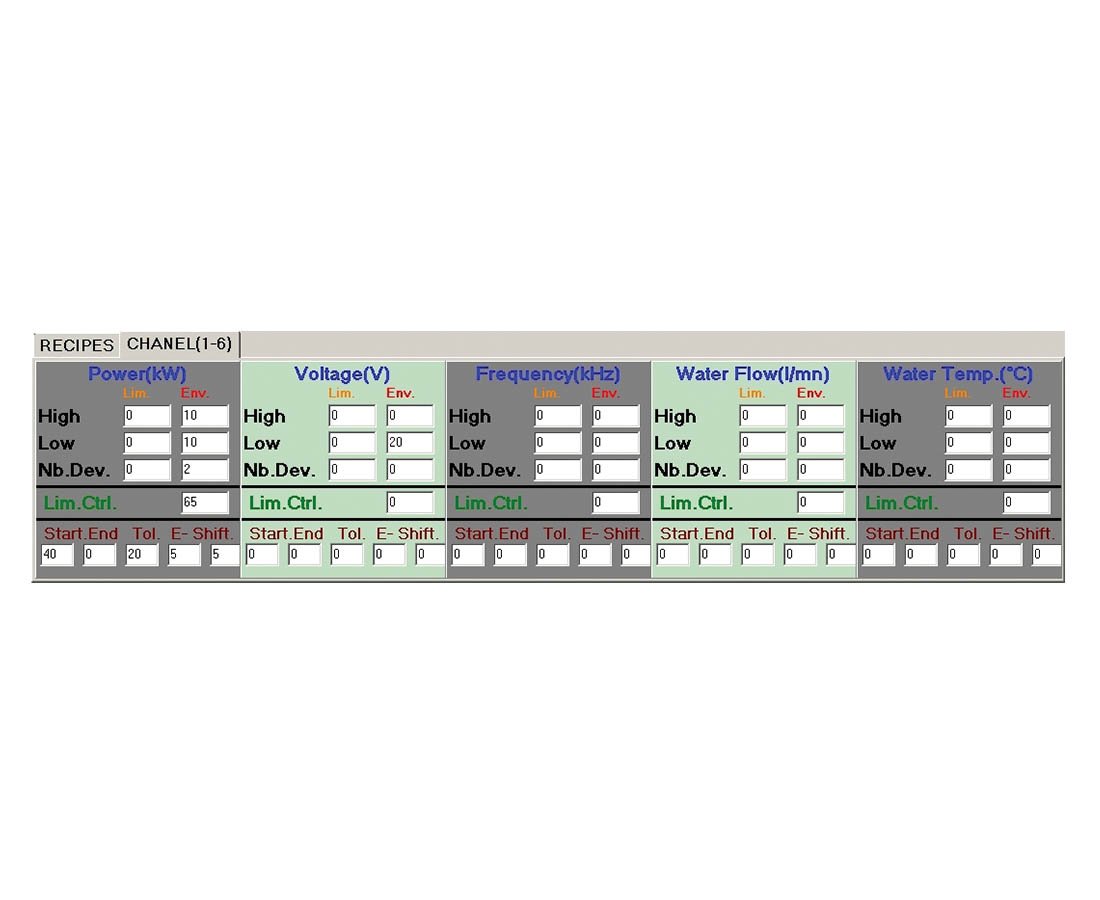

- PARAMETER SET POINTS AND ALARMSPROTHERM 9800 INDUCTION allows you to enter High, Low, and the number of accepted deviations for each of the monitored parameters. This feature enables the system to alarm when one of the parameters established for a certain part is out of the band. Any action taken, once induction is in process, may be determined by the operator.

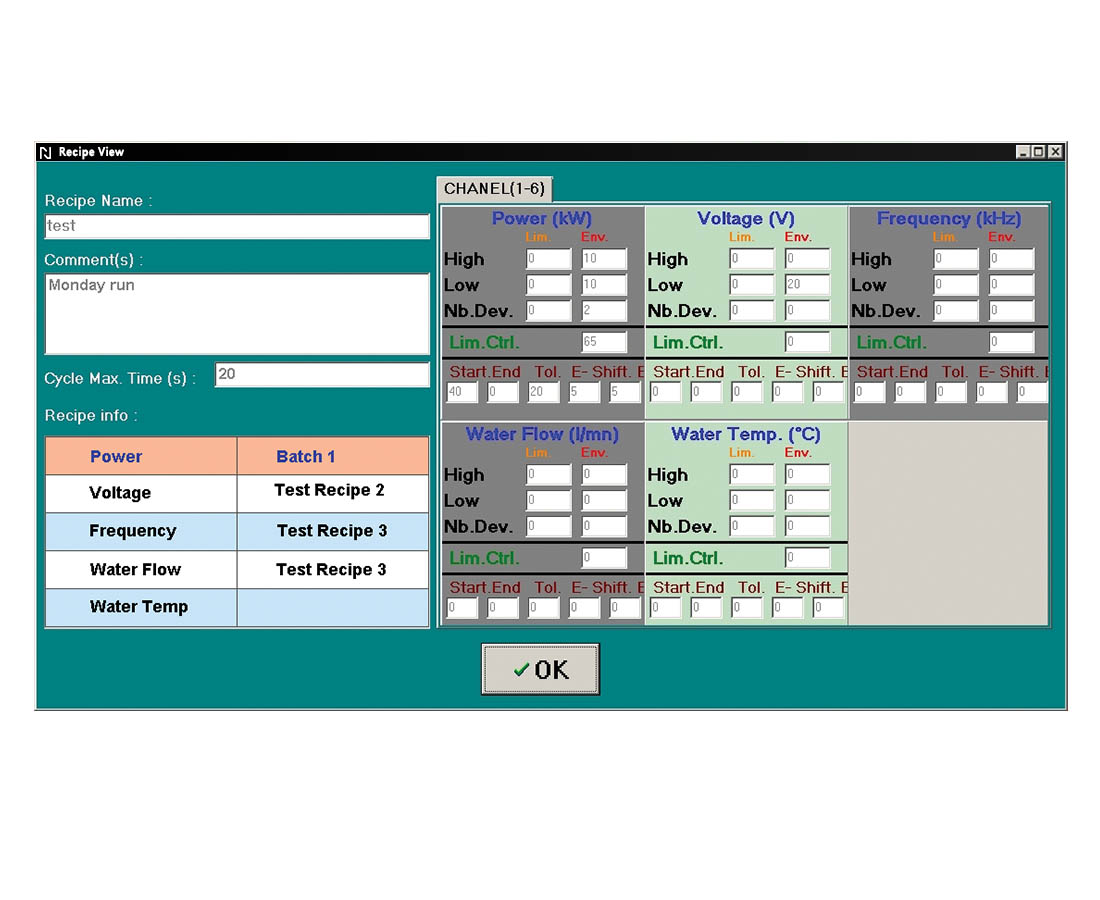

- RECIPE MANAGEMENTPROTHERM 9800 INDUCTION allows the creation of recipes for each part. Parameters are entered for power, voltage, frequency, scan rate, and quench. Recipes are easily copied, modified, and saved.

- LEARNING MODES & REPORTSPROTHERM 9800 INDUCTION can run in Learning mode. In this mode, basic parameters of the part are entered into the system, and the part is processed accordingly. If the results of metallurgical test performed on the hardened part are not favorable, the parameters are corrected, and the next part is processed. When uniformity is attained, the optimal recipe is saved for that part.