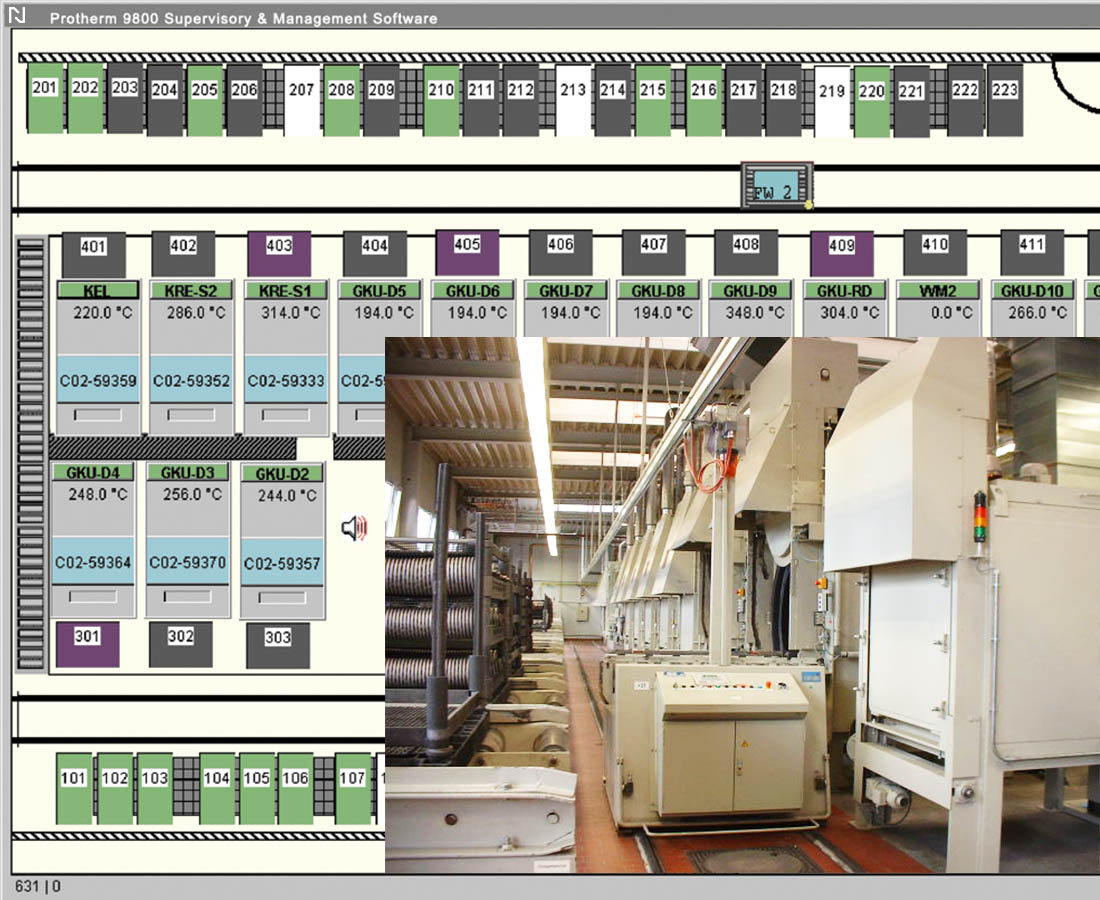

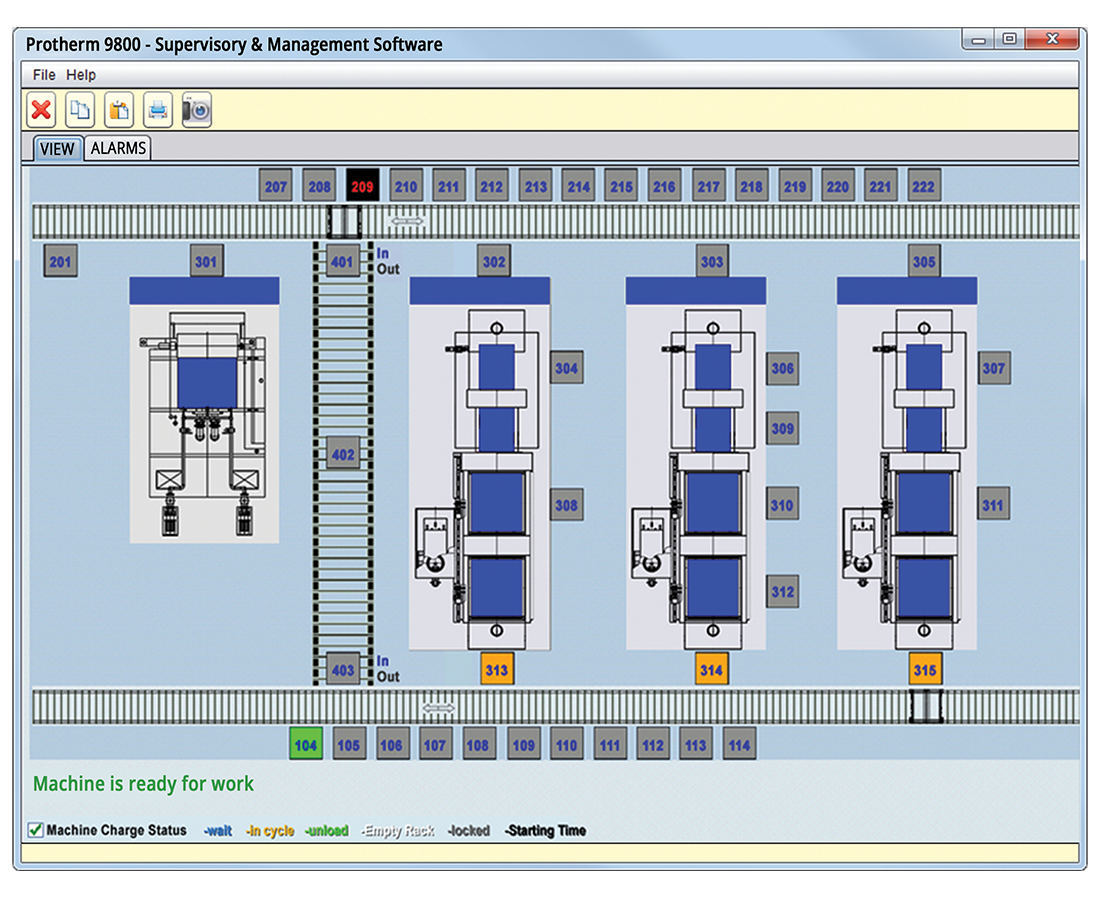

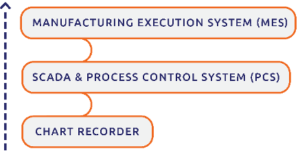

The system structure is based on three scalable tiers with add-on modules for specific requirements. The Protherm 9800 Chart Recorder basically offers batch-based production logs, alarm and event logging. It can be upgraded to the full Protherm 9800 SCADA & Process Control System (PCS), which includes the chart recorder features plus recipe interface for various furnaces, internal programmer functions, the Process-Electronic Diffusion Simulation Model, lab reports, maintenance scheduler and more. The SCADA & PCS tier can be further upscaled to the Protherm Manufacturing Execution System (MES) with such modules as Equipment Usage Calculation, Outage Documentation, Consumption Evaluation, Part Serial Number Tracking, Load Planning & Tracking System, Lights-out Automation and Statistical Process Control.

BASIC MODULES

- Database: Module for storing and accessing materials, treated parts and treatments database

- Monitoring of Jobs: Process control through the use of treatments and controllers

- Alarms: Real-time monitoring of jobs being processed

- Furnace Capacity: Furnace load capacity analysis

- Load Sequence / Job Planning:Module for planning optimal load sequences and jobs

- Archiving:Archiving of heat treatments (furnace log book)

- Reporting: Reporting of heat treatment processes

- User Access Management Defining user access, rights and privileges through password protection

OPTIONAL SOFTWARE MODULES

- Quality Control Module: Comprehensive quality control system. Fully configurable.

- Utilization Module: Calculation of furnace utilization, including statistics on tonnage, down times, occupancy and utilization for a single furnace, group of furnaces, a treatment, a part or a group of parts.

- Scheduling Module: Optimization of the process scheduling with a graphical display of the planned and measured values, the furnace downtime and warnings and errors.

- Alarm Notification Module: Transfers alarms to a specified communication device, e.g., phone, mobile, or email.

- Remote Service Module: Remote support and system maintenance using a modem, ISDN-router or Internet tunneling.

- Integration Module: Integration of customer specific extensions and modifications. Possibility of incorporating additional equipment such as a PLC and controlling and recording their values.