- Calculation of the expected hardness distribution – carbon and/or nitrogen profiles for the required case depth

- Progression of process curves with zoom options

- Profile curves of the expected carbon and/or nitrogen and hardness distribution with zoom options

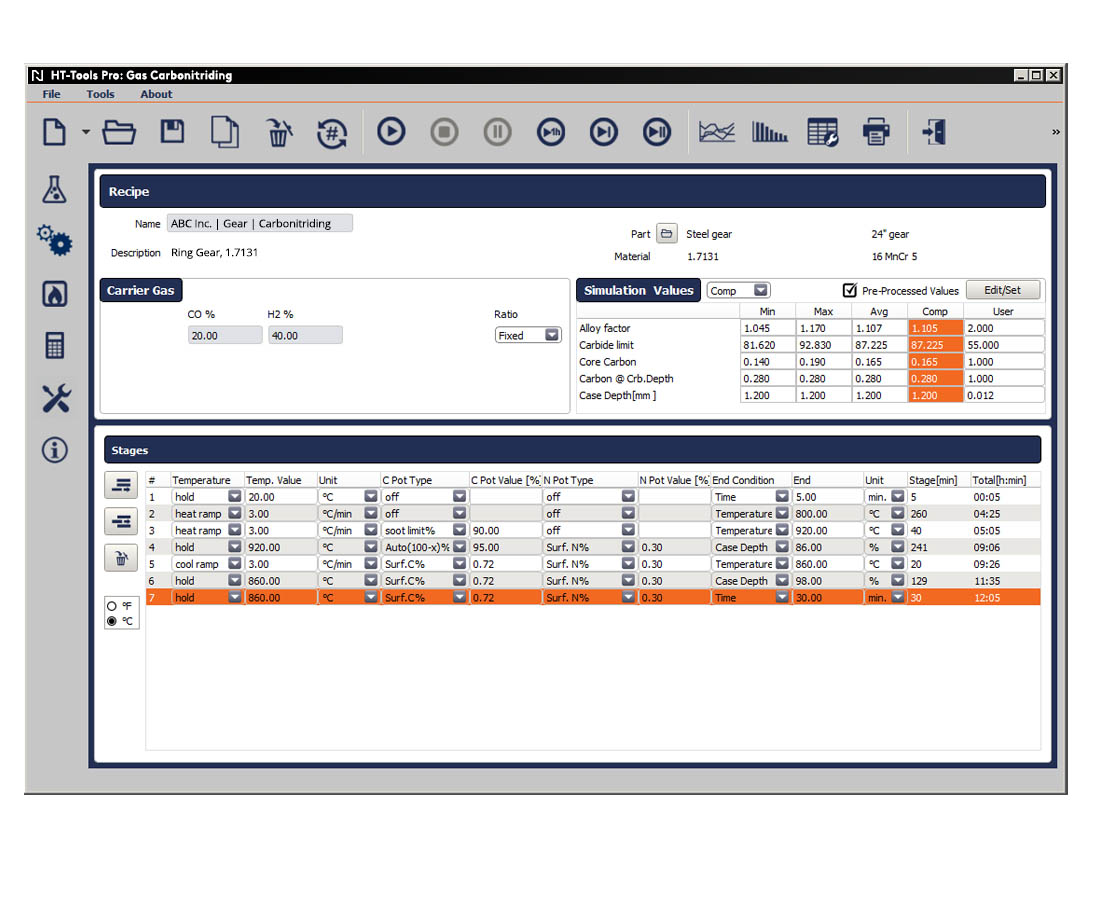

- Database of recipes with automatic calculation of limits versus soot formation and carbide/nitride precipitation

- Materials database that can be populated with the chemical composition of various steels

- Possibility of accounting for a part’s geometrical characteristics

- Short recipe optimization time

- Faster sampling-to-production time

- Possibility of in-flight parameter modifications reduces the need for expensive testing

- Recipes can be transferred to any PROTHERM controller via the PROTHERM 9800 production management software

- FURNACES & TECHNOLOGIESFIND OUT MORE ABOUT OUR FURNACE AND TECHNOLOGIE SOLUTIONS

- HEAT TREATING SERVICESFIND OUT MORE ABOUT OUR HEAT TREATING SERVICES

- PROCESS & FLOW CONTROLSFIND OUT MORE ABOUT OUR PROCESS AND FLOW CONTROL SOLUTIONS

- SERVICE & SUPPORTLOOKING FOR SERVICE OR SUPPORT ON OUR PRODUCT AND SERVICES ?

- INDUSTRIES & PROCESSES

- COMPANYFIND OUT MORE ABOUT NITREX AND WHO WE ARE