OPERATING CHARACTERISTICS

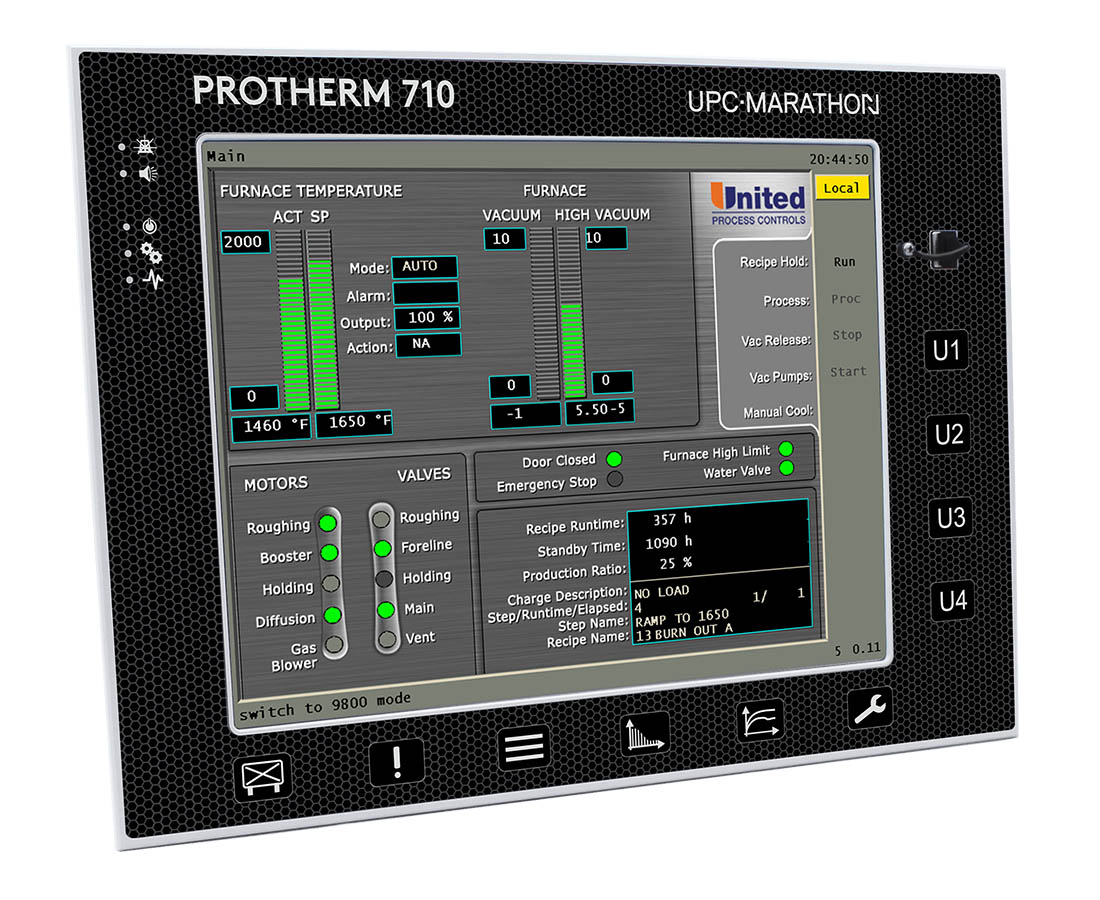

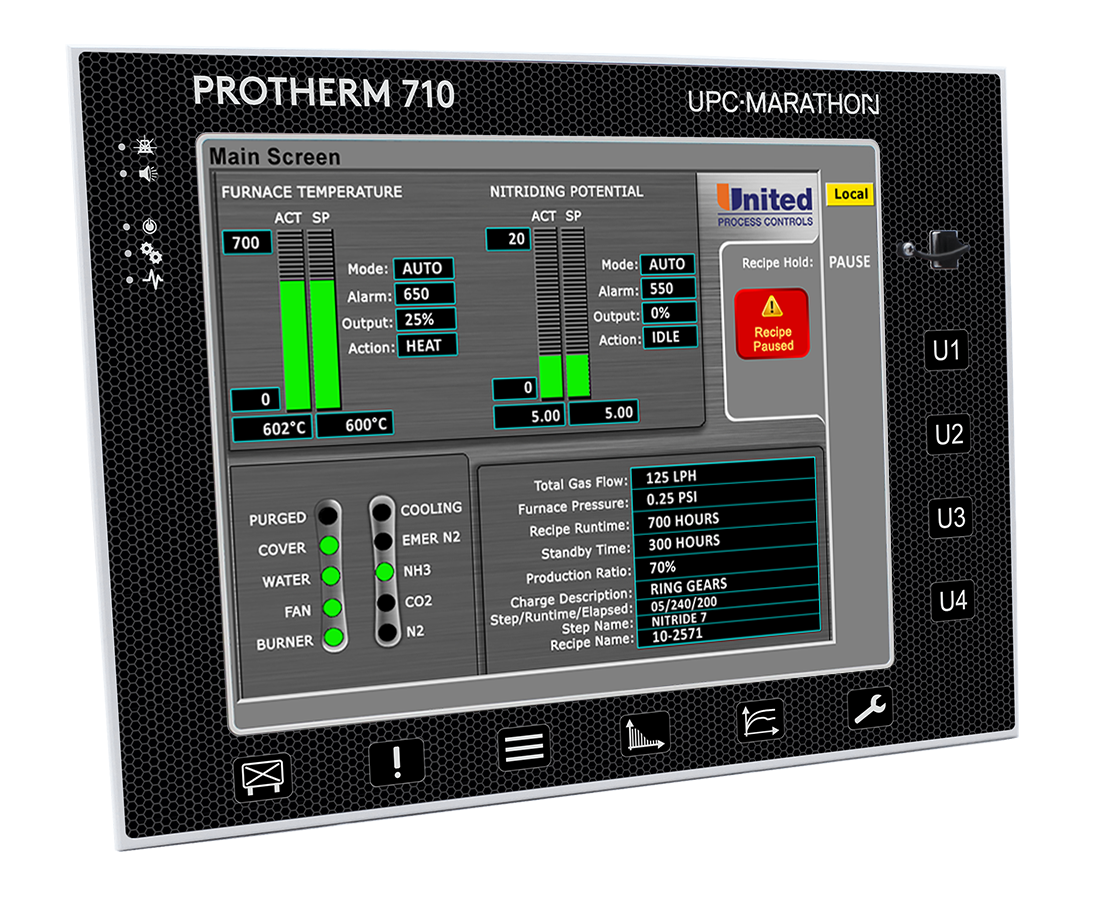

- Control knob or Touchscreen enables user to select input fields and enter data

- Function keys are used for accessing the most important functions

- Users access to different functions is password protected

- A PC keyboard can be connected through a USB port

INTEGRATED WEB SERVER

- A remote computer can be connected to the device through a standard web browser

- The treatment logs in PDF format and in ASCII-CSV format are kept for 30 days. They can be downloaded and then further processed with any appropriate PC software (e.g. Microsoft® Excel)

- A powerful Java based configuration tool can be downloaded and installed on a local PC for configuring all the device parameters

BUILT-IN FUNCTIONS

- Mathematical model for calculating atmospheric parameters from gas inputs and sensor values

- Real-time carbon and/or nitrogen diffusion calculation

- Hardness profile calculation based on chemical composition, carbon or nitrogen content in the material, and quenching parameters

SPECIAL PROCESS DIAGRAMS

- Diagrams that display the actual state of a load during a process

- Carbon content and hardness profiles

- Nitrogen content and hardness profiles

- Fe-C state diagram

- Fe-N Lehrer diagram

- Fe-N-C NICARM diagram

- Fe-O state diagram

CONFIGURATION

- Special menu for the configuration of the integrated controllers

- PID set-up

- Adjustment and setting of control parameters

- Real-time graph for displaying the control parameters and tuning the settings