A leading metal injection molding company is bolstering its manufacturing capacity with the addition of two large-size horizontal vacuum furnaces for sintering and debinding MIM products and components.

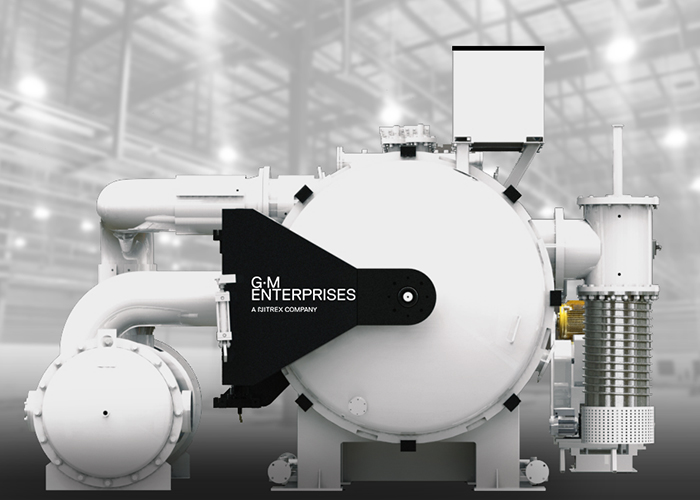

G-M Enterprises, a Nitrex company, has received a multimillion-dollar order from a global manufacturer of metal injection molding (MIM) products to supply two large-size horizontal vacuum furnaces. These 2-Bar vacuum sintering furnaces feature a work area of 36” wide x 30” high x 84” long (900 x 762 x 2100 mm), 4400 lb. weight capacity, a maximum operating temperature of 2600°F (1430°C), and uniformity of +/-10°F (+/-5.5°C). Integral to the vacuum system configuration is an efficient multistage debinder trap system designed to thermally extract binder from the parts. Sintering and debinding occur in a single cycle using a robust and unique system design that is optimized to handle the maximum load capacity the furnace is designed for. Consequently, there is never a need to operate below the rated load capacity to achieve the required part quality. The high-temperature sintering process also ensures a high-quality finished part surface in terms of density, porosity, mechanical resistance, and aesthetics.

“This latest order comes from a customer we have had a strong cooperation with, and which will be part of a series of multiple furnaces provided by G-M Enterprises over the past decades. G-M Enterprises was carefully selected because of our ability to meet the customer’s large-scale design requirements and to optimize the furnace performance, our competitive lead time as well as the predictable and repeatable metallurgical results,” said Michel Frison, VP Global Sales, Nitrex and G-M Enterprises.

“I want to thank our loyal customer for their trust as well as Mr. Suresh Jhawar, G-M Enterprises Senior Adviser, and the whole team at G-M Enterprises who were instrumental in securing this order,” added Michel Frison.

The first of the two furnaces will be delivered this year and the second is scheduled for commissioning in March 2021.

About G-M ENTERPRISES

G-M Enterprises, a Nitrex Company, is a leading manufacturer of high-temperature vacuum furnaces and hot zones developed and proven for all types of heat-treating applications from simple steel to high-temperature nickel-based alloys and titanium and for a variety of industries, including aerospace, nuclear, power turbine, medical, tool and dies, MIM, and 3D additive, among others.

With over forty years of experience serving the thermal processing industry, G-M Enterprises is a reliable partner that clients can trust to meet heat processing and application objectives with a variety of innovative solutions, timely manufacturing, and quality support services. From engineering to manufacturing, field service maintenance/installation technical groups, and after-market parts support, G-M Enterprises adds value to every system.

Today, thanks to being part of NITREX, www.nitrex.com, and its global network of companies, G-M Enterprises’ customers now have access to a full range of products, services, and scalable solutions, from turnkey vacuum systems to nitriding/nitrocarburizing systems, process and flow controls, automation solutions, as well as heat treating services.

MASTERING STRENGTH. WORLDWIDE.